Down Hole Video Services

Evaluation

Logging While Drilling

Open hole Wireline Services

Cased hole Wireline Services

LWD and WL Log Evaluation

KAPCO Down Hole Video Tools

KAPCO Down Hole Video Tool runs with Surface Read Out(SRO) mode by E-line or Memory Mode by Slickline or Drilling Pipe. It is useful in Oil & Gas well industry, water well industry, as well as in geothermal and gas storage bank inspection.

By updated high-temp lens modules, it achieves down view and sideview at the same time, due to the big view angle, the tool will cover the entire downhole casing inner wall from 2 inch up to 17 inch casing/tubing. The video quality has been improved by unique multi-source illumination model and lens design.

KAPCO Down Hole Video Tools are easily transportable by air transportation or other rapid transit systems.

Features

Fully digital bi-directional transmission system gives full control over video functions and ensures maximum flexibility. The intensity of the LED lights can be controlled from surface so that in reflective environments such as chrome tubing the lights can be reduced whereas in a dark environment the lights can be increased.

Both the picture resolution and refresh rate are controllable from surface. When running in the hole or monitoring a dynamic environment such as fluid entry, a higher frame rate can be delivered by reducing the resolution. Similarly when inspecting a stationary object a high resolution picture can be taken but with lower update rate.

The KAPCO Down Hole Video has dedicated high intensity LED lights ensuring the best possible lighting of looking images. The lens has a wide range of depth of field from 1’ up to 8’. It also has a big view of angle up to 120 degree; the side-view lens can be rotated with the motor rotation. So you can see the subtle corrosion or cracks, and it will provide you with a clear picture of casing wall.

The KAPCO Down Hole Video has equipped the world fast telemetry module, and make sure the picture has the best quality and refreshing rate compare with competitors.

Applications

- Imaging dropped objects and wellbore fish

- Mechanical inspection of wellbore hardware

- Inspection and monitoring of corrosion and erosion

- Detecting water/gas/oil entry

- Perforation checking

- Coal bed methane wells

- Open hole imaging

Casing collar

Safety Valve

Technical Specifications

- Diameter: 54 mm (2-1/8”) or 38mm (1-1/2”)

- Length: 1.80 m (side-view & down-view)

- Pressure rating: 1,5000 psi

- Max Temperature: 150℃(302℉)

- Camera: Black and white

- Focal length: 1’ up to infinity

- Connection: 1 3/16-12

- View of angle: Side-view / Down-view ( 120°)

- Transmission rate: 1.5 frame/s mono-cable @ 460p*460p

- Surface video: Continuous video

- Casing/tubing size: 2” to 17”

- Well fluid: Water/Gas/Oil well

- Cable: 7/32”, 5/16” mono-conductor cable

- Logging depth: 7,500 m

- Logging mode: Surface Read Out or Memory

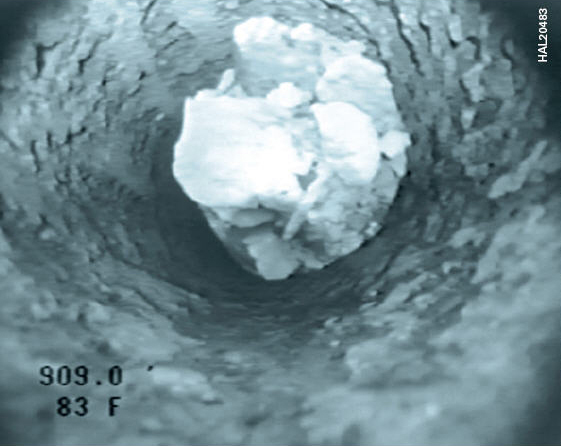

Downview Camera – Cement Plug

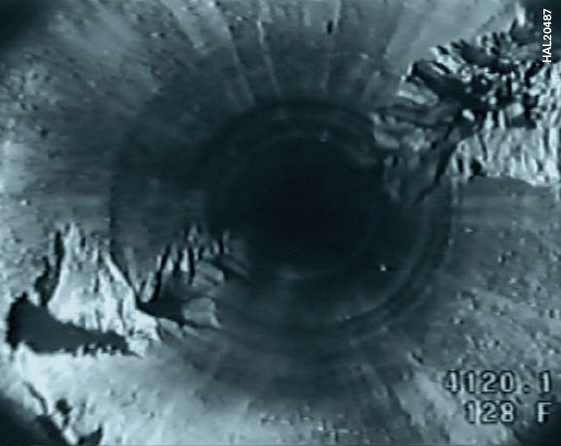

Downview Camera – Damaged Casing